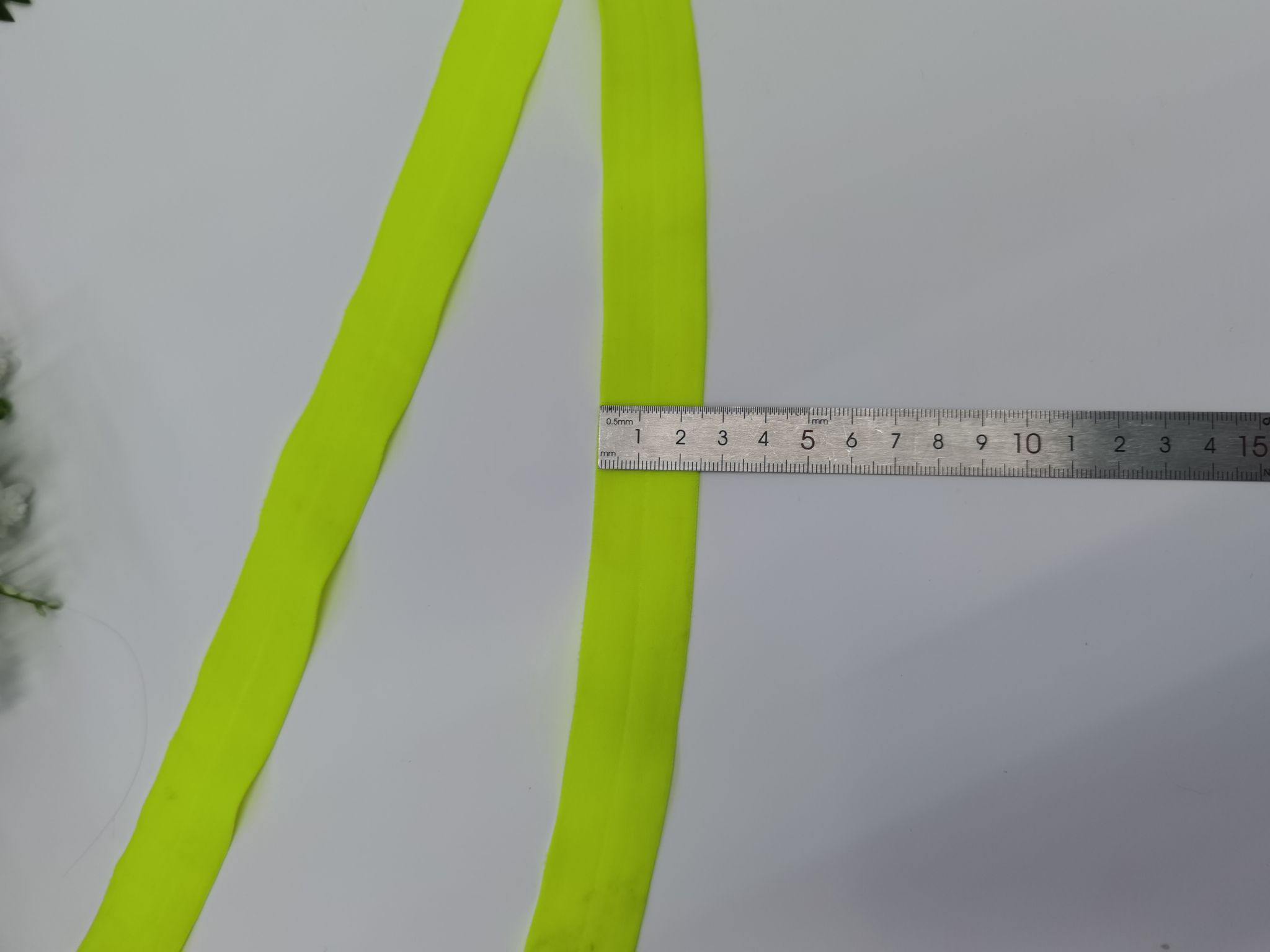

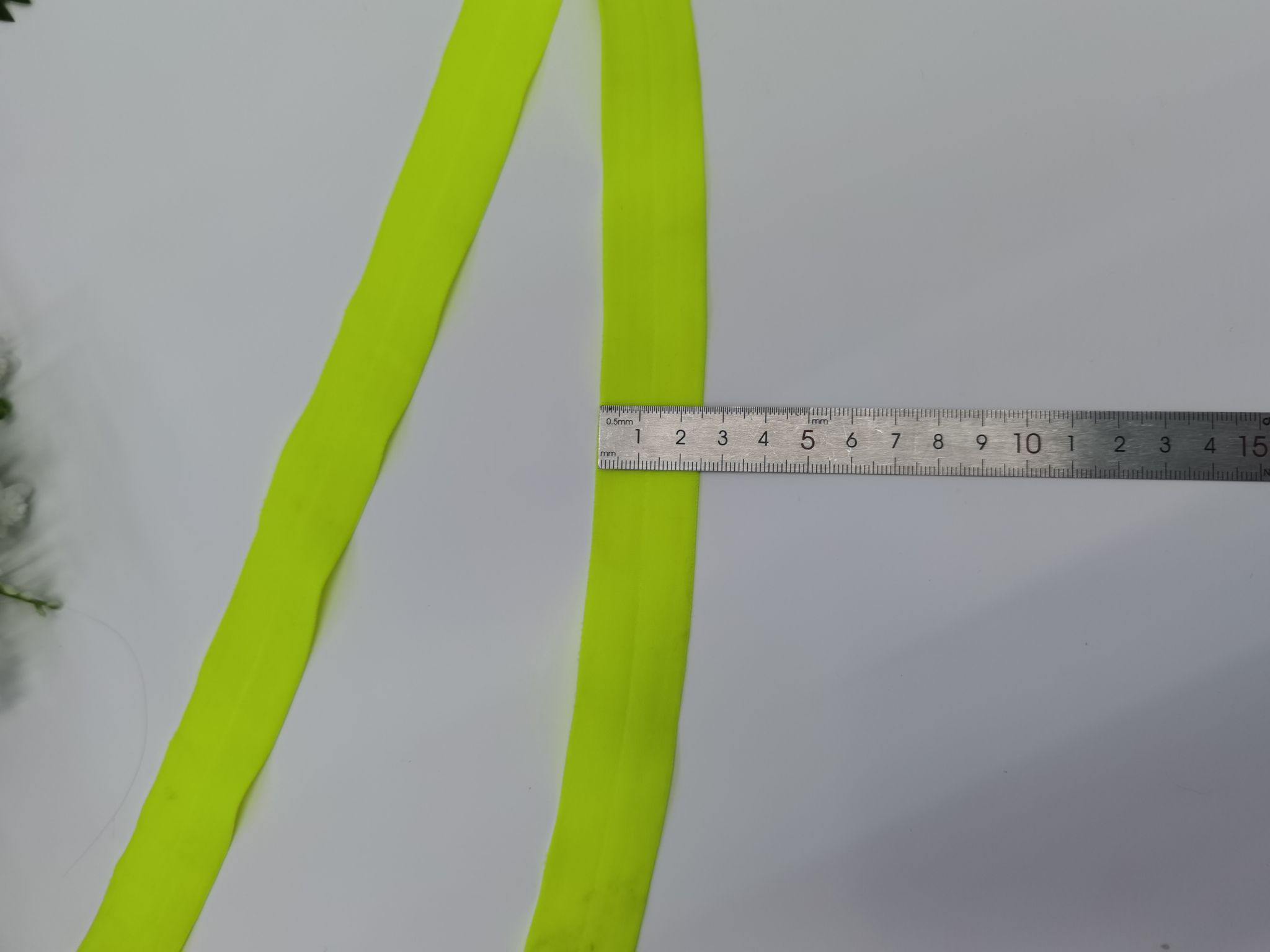

In the field of industrial manufacturing, the choice of materials directly affects the quality and performance of the final product. Today we want to introduce a series of products that we have carefully built-from 0.4 to 4.0mm edge size selection. These products have won the favor of many customers for their wide range of uses and excellent performance.

Explore a wide range of application scenarios for 0.4-4.0 edge products

This series of products is used in many industries due to its precise design and high-quality materials. For example, in the machinery manufacturing industry, they can be used to make precision parts; in the construction industry, they are often used to process various decorative plates or build structural parts. In addition, due to its large thickness range and high precision, it can also meet the special needs of the aerospace field.

Why choose our factory direct sales model?

Compared to traditional dealer channels, the use of direct sales from manufacturers to consumers has significant advantages. First of all, the problem of cost increase caused by intermediate links is reduced, making the terminal selling price more reasonable and friendly to the people. Secondly, it can quickly respond to changes in market demand to adjust inventory levels or introduce new products to cater to the preferences of different users. Last but not least, quality control is stricter because each process is under its own control, so each batch can reach a unified standard.

In-depth interpretation of product features and specifications

This series provides a wealth of thickness options (from a minimum of 0.4mm to a maximum of 4.0mm) to meet the requirements of a variety of processing technologies. At the same time, a wide variety of surface treatments, such as polishing and wire drawing, further enhance the appearance and enhance the corrosion resistance. It is also worth mentioning that all raw materials are made of high quality steel to ensure long-term reliability will not be easily deformed and broken.

Practical Case Sharing: How to Reduce Costs through Precise Purchase

a furniture manufacturer originally used imported similar products, but the high price squeezed the profit margin, so he turned to the scheme provided by the domestic brand and found that not only the unit price was lower but also the delivery time was greatly shortened, thus effectively relieving the pressure of cash flow. at the same time, he also obtained the full guidance of the technical support team to help solve some problems encountered during the early running-in period and truly realized a win-win situation.

Revealing the strict quality control system behind the production process

every finished product that reaches the customer has to go through multiple inspection procedures before it can leave the factory, including the on-line monitoring of raw materials entering the factory and the full inspection after completion. only in this way can we ensure that the product quality is always in the controllable range to provide the most satisfactory service experience for users.

Personalized customization options help achieve the unique needs of enterprises

in addition to standardized commodities, we also attach great importance to meeting the special requests of individual enterprises, such as special shape cutting, non-standard packaging forms or even printing LOGO logos, etc. as long as specific ideas are put forward, we will try our best to cooperate with each other. after all, the success of each partner is a very important milestone for us and deserves to be celebrated together!