New trends in plate purchase: why accurate thickness is the key

In today's fast-growing manufacturing and home improvement industries, consumers' requirements for materials are becoming more sophisticated. Especially for the choice of plate, "precise thickness" has become one of the indispensable key factors.

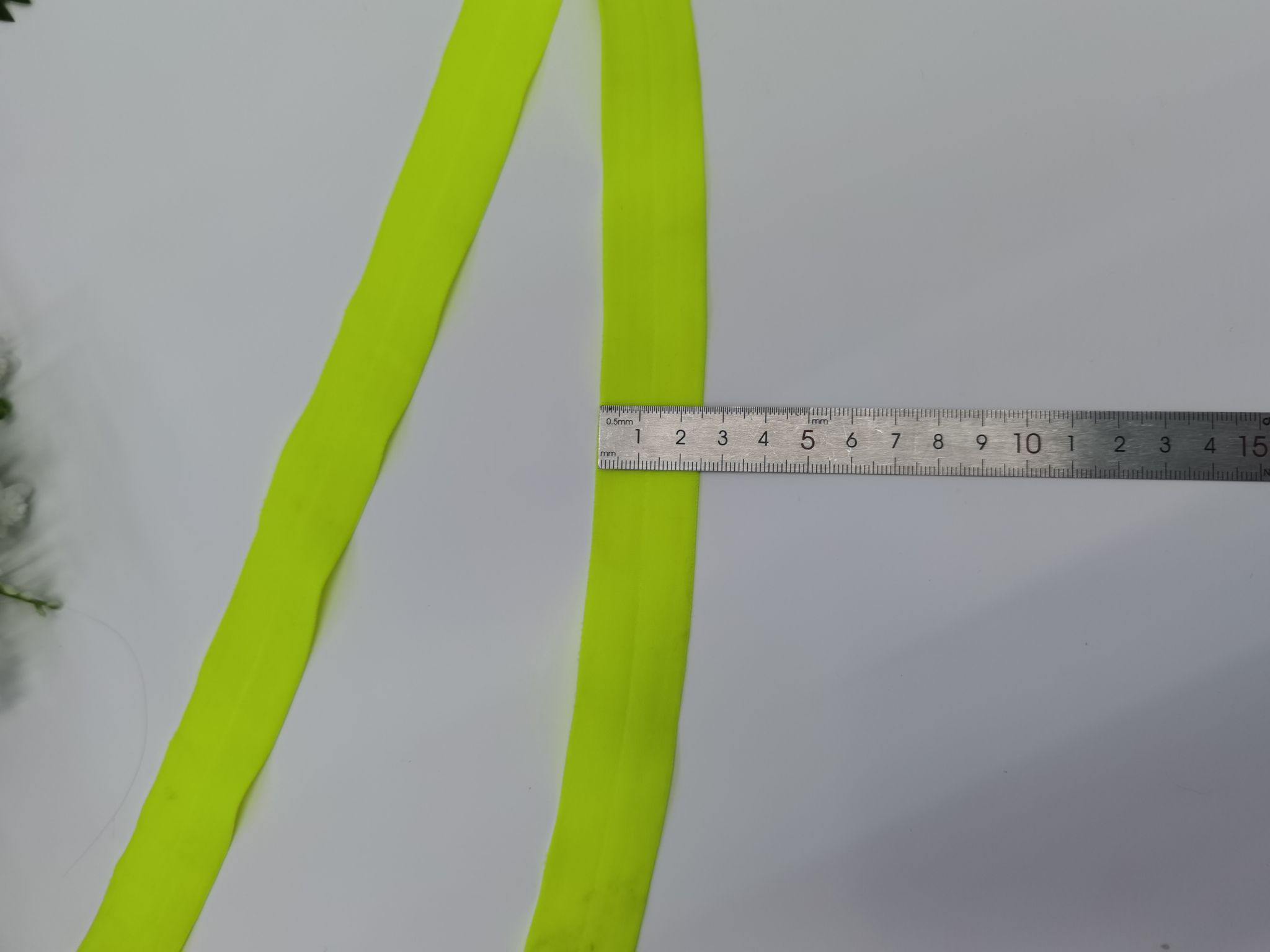

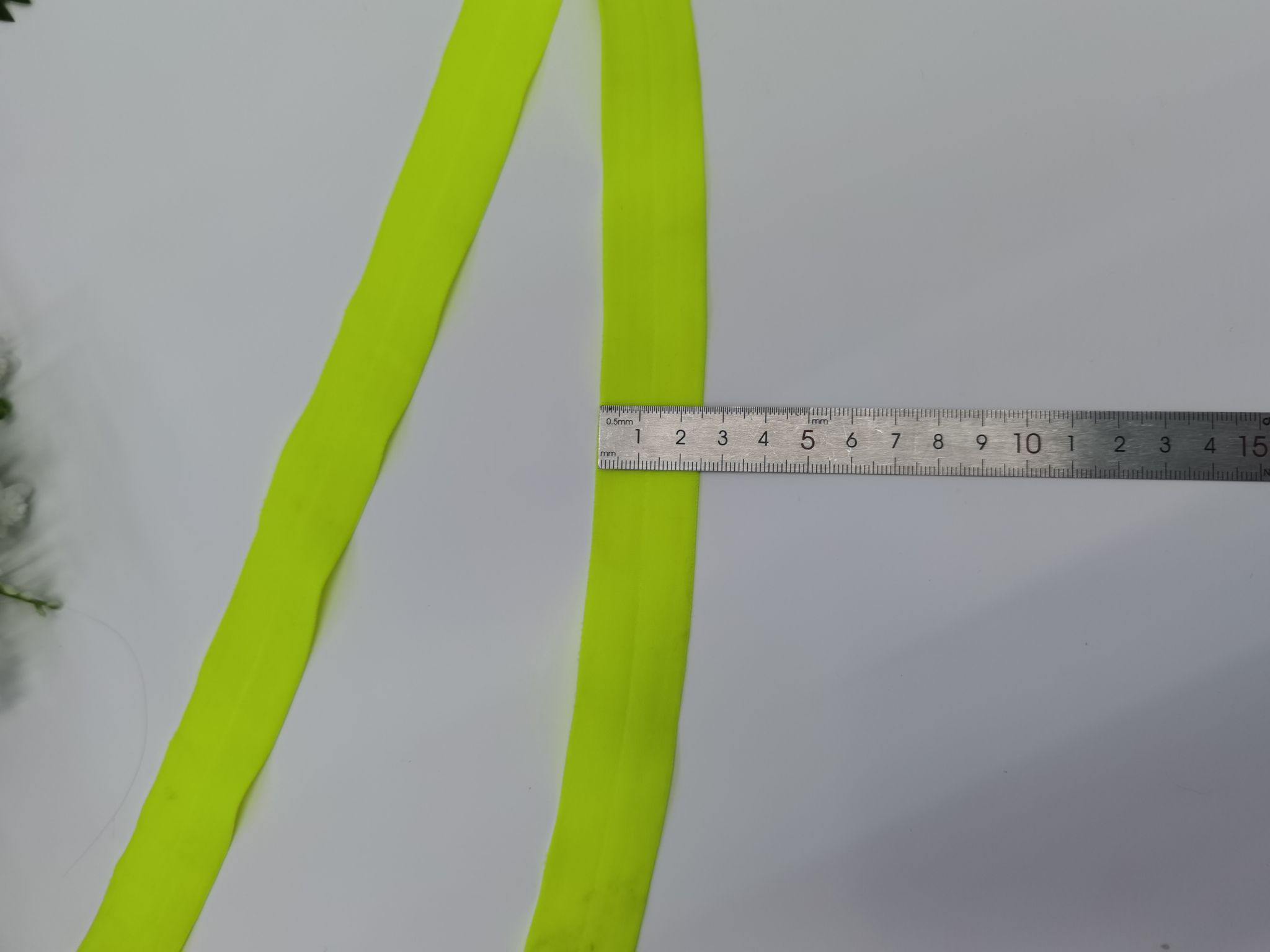

Take the product we recommend this time as an example. This is a high-quality sheet directly sold by the factory and the thickness range is strictly controlled between 0.4 and 4.0mm. Its emergence not only redefines the market's cognitive standard for "precision", but also provides more possibilities for all walks of life.

analysis of thickness subdivision advantages: multifunctional charm of 0.4-4.0mm plate

the biggest feature of this board is that its thickness covers a very wide range (from 0.4mm as thin as paper to 4.0mm as solid and durable), which can meet the needs of various complex scenes. For example, in the field of home decoration, the lighter and slender parts are very suitable for making wall veneers or furniture surface coatings; while in machining, you can rely on the thick and solid end to build more complex parts. structure.

In addition, because each layer is precisely calculated and polished, no matter which size is selected, there will be no excessive error-this feature allows customers to flexibly adjust the scheme according to their actual situation without worrying about the risk of subsequent rework.

Disclosure of Industrial Standards: How to Ensure Quality Stability of Each Sheet

In order to provide users with the most reliable service experience, our production team always adhere to the most advanced technology and strict testing process for quality control.

First of all, a very high standard threshold has been set from the beginning of the raw material selection process. Only those materials that have been screened layer by layer and passed a number of index tests can enter the next process stage. Then it is to use the automatic production line to complete a series of operation steps such as cutting and pressing. In the whole process, there are professional and technical personnel to supervise and guide the whole process, and regularly sample and check whether the finished product meets the expected set parameter requirements.

Finally, it will have to go through a comprehensive and detailed re-inspection process before it can be officially packaged and delivered to you. This series of rigorous measures together cast today such a trustworthy brand image.

Application scenario measurement: a one-stop solution from home decoration to high-end manufacturing

With the blessing of many of the above superior attributes, the sheet has been successfully applied to many practical projects and achieved excellent performance. For example, a well-known household appliance manufacturer introduced it as a core component into the new refrigerator door panel design scheme, which not only significantly improved the overall aesthetics but also greatly reduced the weight burden. Several other large construction companies have also deployed this technological achievement on a large scale in the external wall dry hanging project, effectively solving the pain points of traditional stone installation difficulties and high maintenance costs.

In addition, some DIY enthusiasts also love the unlimited creative space brought by such products-whether it is to create personalized picture frames or assemble simple lockers, etc., they can easily do it without pressure.

Customer Case Sharing: A True Story of Value Enhancement from High Quality Plates

Mr. Zhang is the owner of a small wood processing plant. Since switching to this new system, the business volume has achieved a qualitative leap in growth. "In the past, there was always a serious loss of customers due to unstable product quality," he sighed, "but now there is no need to worry about this problem at all!" It turned out that they often encountered the dilemma of high scrap rate due to size deviation before, but all these problems were solved after replacing them with the current batch of high-performance materials.

Another Ms. Li is a keen artisan. She said that she especially likes to use this kind of material for sculpture. "They feel smooth and easy to cut and shape, plus the rich and varied colors and textures can inspire endless sources of inspiration." As she said, it has indeed opened up a new world for countless creators.