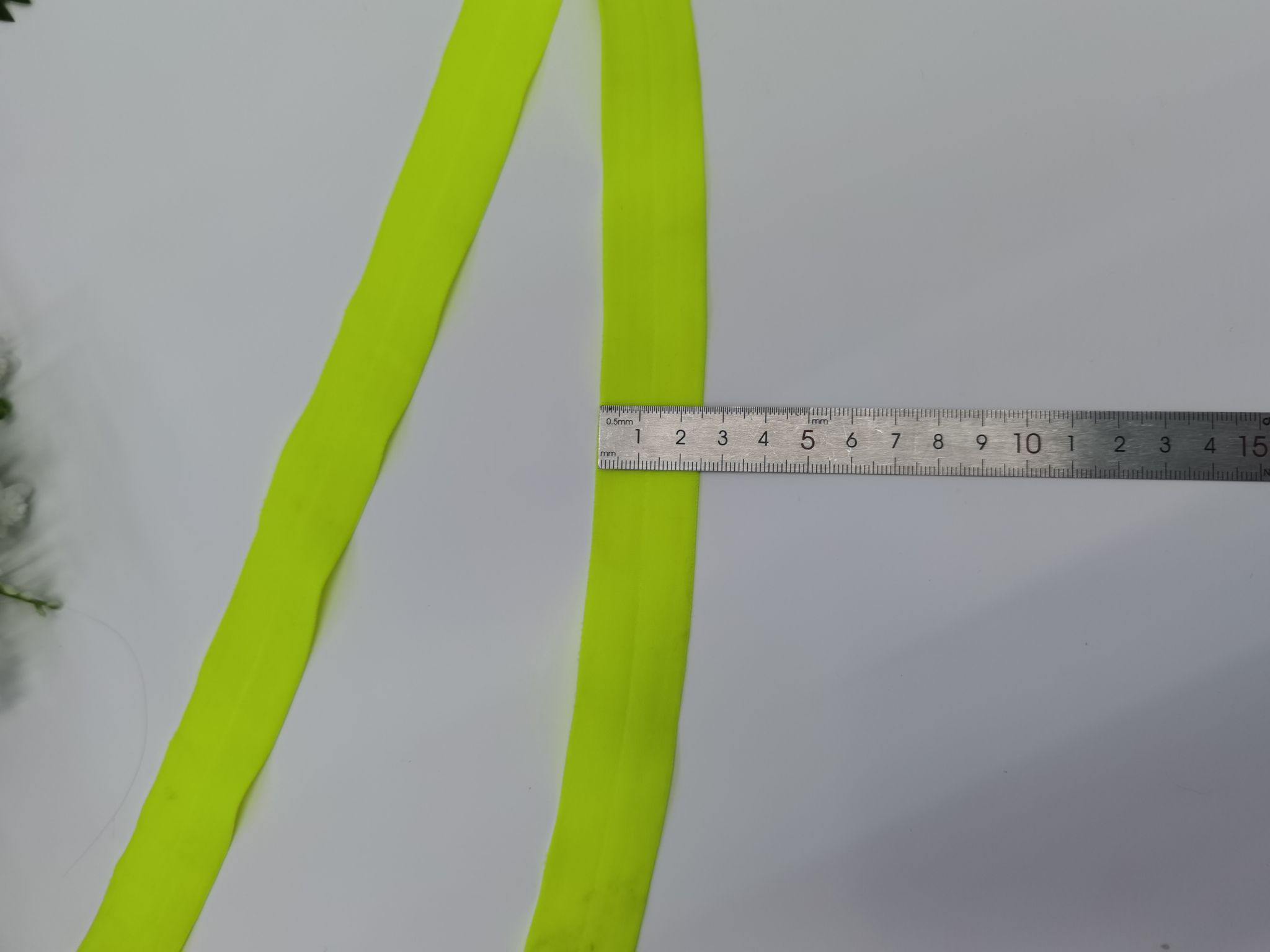

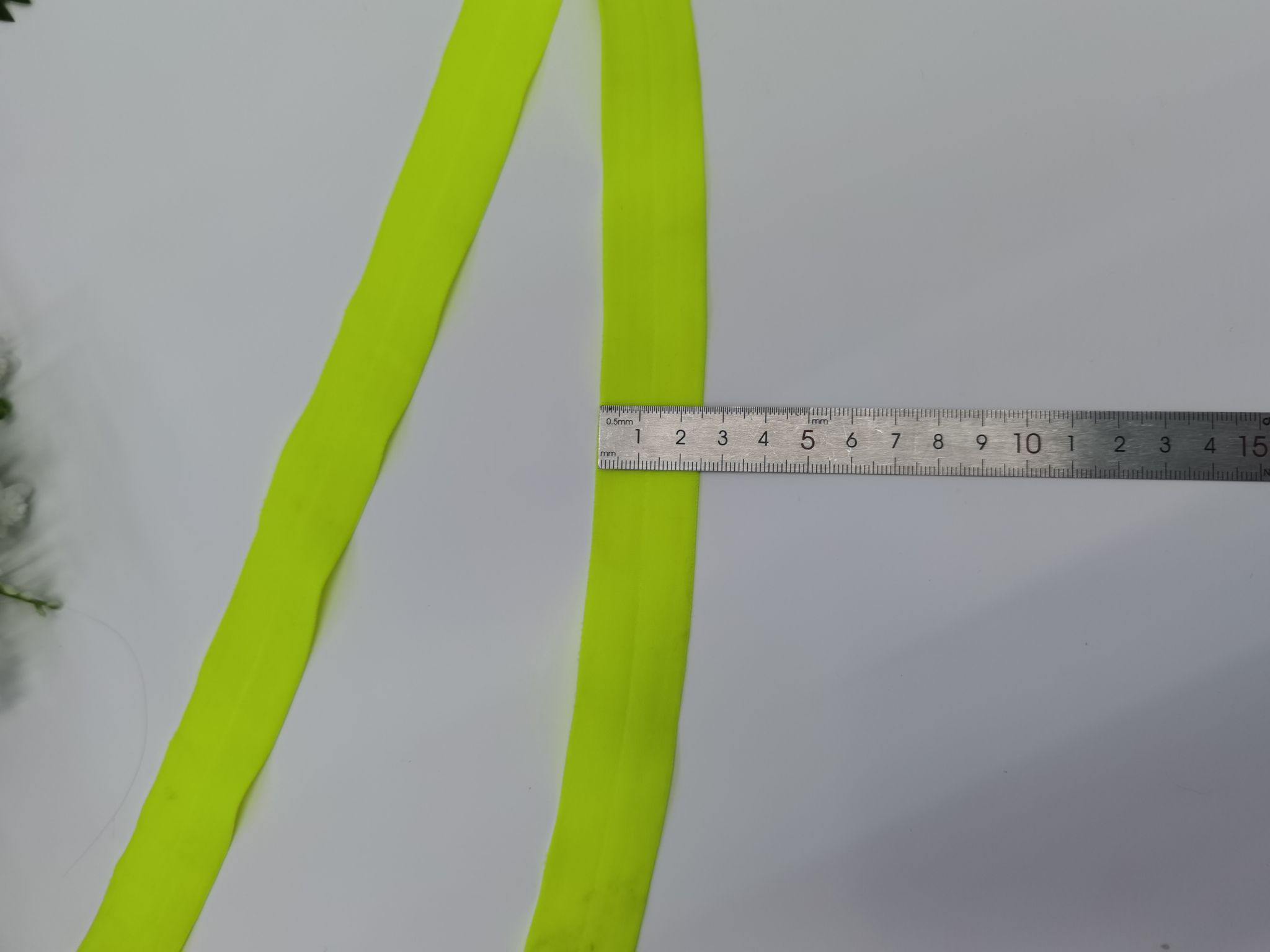

With the continuous development of industry and manufacturing, the demand for high quality raw materials is also increasing. Among them, the edge material, as a foundation but an indispensable part, is receiving more and more attention. Today, we will learn more about the unique value of these high-quality edge products directly supplied by the factory and covering the thickness range from 0.4mm to 4.0mm.

First of all, it is worth mentioning that the uniqueness of these edge products is that they can meet the needs of various usage scenarios. For those applications that pursue the ultimate lightweight design, only less than half a millimeter thick is undoubtedly a perfect choice; in other areas that require higher compression resistance and toughness, you can consider choosing a stronger version larger than two millimeters.

Next, we will turn our attention to the specific practical aspects of this problem-that is, why should we give priority to the source of goods from the manufacturer itself? Direct procurement from the original factory can not only ensure that all goods are checked through the strict quality control process before delivery, but also enjoy a more favorable price policy.

In order to better prove the authenticity and feasibility of the above views, we can use several successful business examples to illustrate. For example, a well-known furniture brand began to introduce this new edge material on a large scale a few years ago for its high-end custom series. Because the material has good anti-scratch performance and beautiful appearance characteristics, greatly enhance the overall product grade level and won the favor of the majority of consumers.

Of course, it is also very important to make an informed choice before buying. It is necessary to be prepared to focus on the features required for different types of projects. Generally speaking, thinner specifications are suitable for decorative lines or detailed treatment work. On the contrary, if it involves the construction part under the condition of large load force, it should tend to choose a relatively thick model to be more reliable.

finally, let's look forward to the future development direction together! With the continuous progress and innovation of science and technology and the trend of continuous change and adjustment of market demand, I believe that in the near future, we will see more emerging technologies and solutions based on such edge materials. Perhaps one day it will not be limited to the traditional physical form of existence ~

To sum up, through this article, we can clearly realize that the high-precision 0.4-4.0mm edge products directly supplied by manufacturers do have many irreplaceable advantages. Both in terms of cost-benefit ratio considerations and practical engineering application performance evaluation point of view are very trustworthy.