In the increasingly competitive field of industrial manufacturing, it is very important to find a key accessory that combines high performance and high cost performance. This hot market manufacturers direct sales from the best 0.4-4.0 edge products, with scientific and reasonable thickness design, stable physical performance and efficient supply mode from the source factory, quickly won the trust and support of our customers.

Why choose edge products with 0.4-4.0 thickness range?

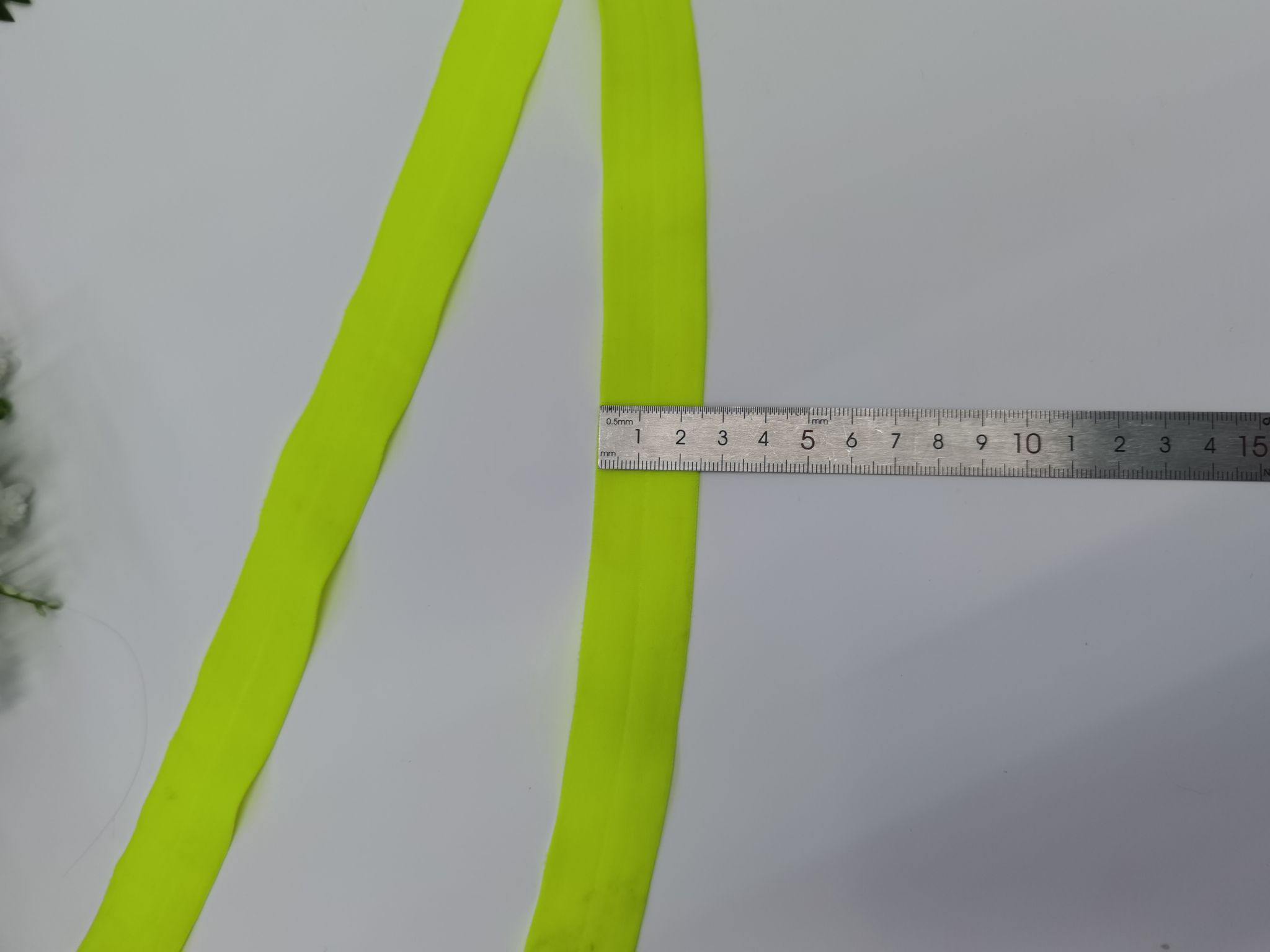

In the face of evolving production process requirements, traditional single-thickness edge components have been difficult to cope with complex environmental challenges. Based on in-depth technical research and user feedback, this series of products have been finely adjusted within the core interval between 0.4mm and 4.0mm, achieving a high degree of unity of strength and flexibility.

whether in stamping or cutting welding and other processes, this specific thickness setting can better fit a variety of equipment parameters, so as to improve the overall utilization rate of materials, effectively reduce the cost pressure of enterprises in the raw material procurement stage.

More importantly, its wide compatibility characteristics make the same system can be adapted to different types of mechanical devices, truly "one material multi-purpose", greatly enhancing the practicality and extensibility of the product.

The unique advantages of the source factory direct sales model

As one of the core products launched by well-known manufacturers in the deep-cultivated industry for many years, this series of edge components rely on the complete industrial chain resources and technology accumulation to build a quality management system covering the entire life cycle.

Compared to the traditional distribution channels layer price increase phenomenon, we adopt a direct-to-end user sales strategy, completely eliminate unnecessary intermediate links, to bring customers a more competitive price program. At the same time, mature flexible production lines can quickly start personalized order production plans according to customer needs, greatly reducing delivery waiting time.

each batch will undergo rigorous inspection procedures before leaving the factory, covering multiple dimensions such as dimensional accuracy measurement, mechanical index testing, etc., only to deliver the highest level of products to each partner.

Strong compatibility for a wide range of applications

Thanks to excellent technical strength and rigorous research and development attitude, this high quality edge component has successfully penetrated into many popular industries such as building materials, electronic product assembly and heavy machinery and equipment manufacturing, and has won the industry professionals.

For example, in the steel structure connection parts of large-scale infrastructure projects, it can act as a load-bearing node to play an important role; while in the automated assembly line, it is embedded in the whole machine structure with its stable and reliable form to assist in the completion of various precision operation tasks.

the technical director of many cooperative enterprises said that since the switch to our standard parts, not only the assembly efficiency has increased significantly, but also the frequency of subsequent operation and maintenance has decreased, thus achieving a win-win situation of improving quality and efficiency in a real sense.

The actual performance of helping enterprises to reduce costs and increase efficiency

The growing number of success stories demonstrates the powerful potential of this innovative solution. Through the data analysis of the operating conditions of several typical customers, it is found that after the introduction of such edge parts, the number of failures and shutdowns of the overall system has been reduced by an average of nearly 20%, and the energy consumption level has also been adjusted to varying degrees.

standardized interface design simplifies the original cumbersome operation process, so that the technical staff can quickly enter the next phase of work deployment. At the same time, the durable nature means that the regular inspection cycle can be lengthened appropriately, and the corresponding manual inspection expenses are also reduced.

is particularly worth emphasizing that, due to the use of green environmental protection concept to guide the development of the whole process, so in the energy conservation and emission reduction policy is becoming more and more stringent in the current environment can still calmly deal with compliance review problems.

to sum up, " factory direct sales from the best 0.4-4.0 edge " is undoubtedly a star item with great investment value in the current industrial supporting market. If you are looking for a safe, reliable and affordable professional accessory option, try contacting our service team for more information! I believe we will use practical action to explain what is called real value for money.