Unlocking a New Era of Industrial Precision | 0.4-How 4.0 Edge Adjustment Tools Reshape Productivity

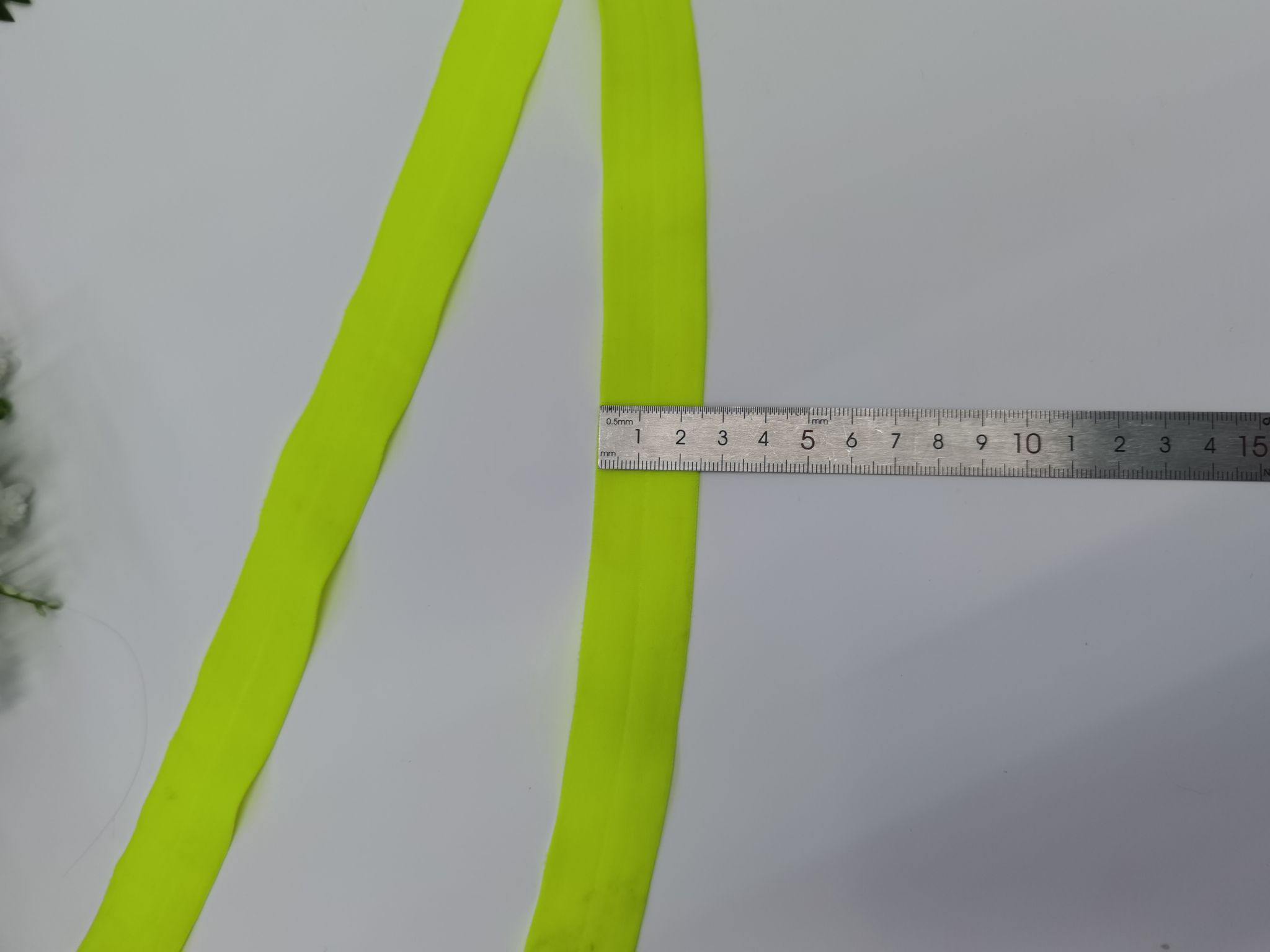

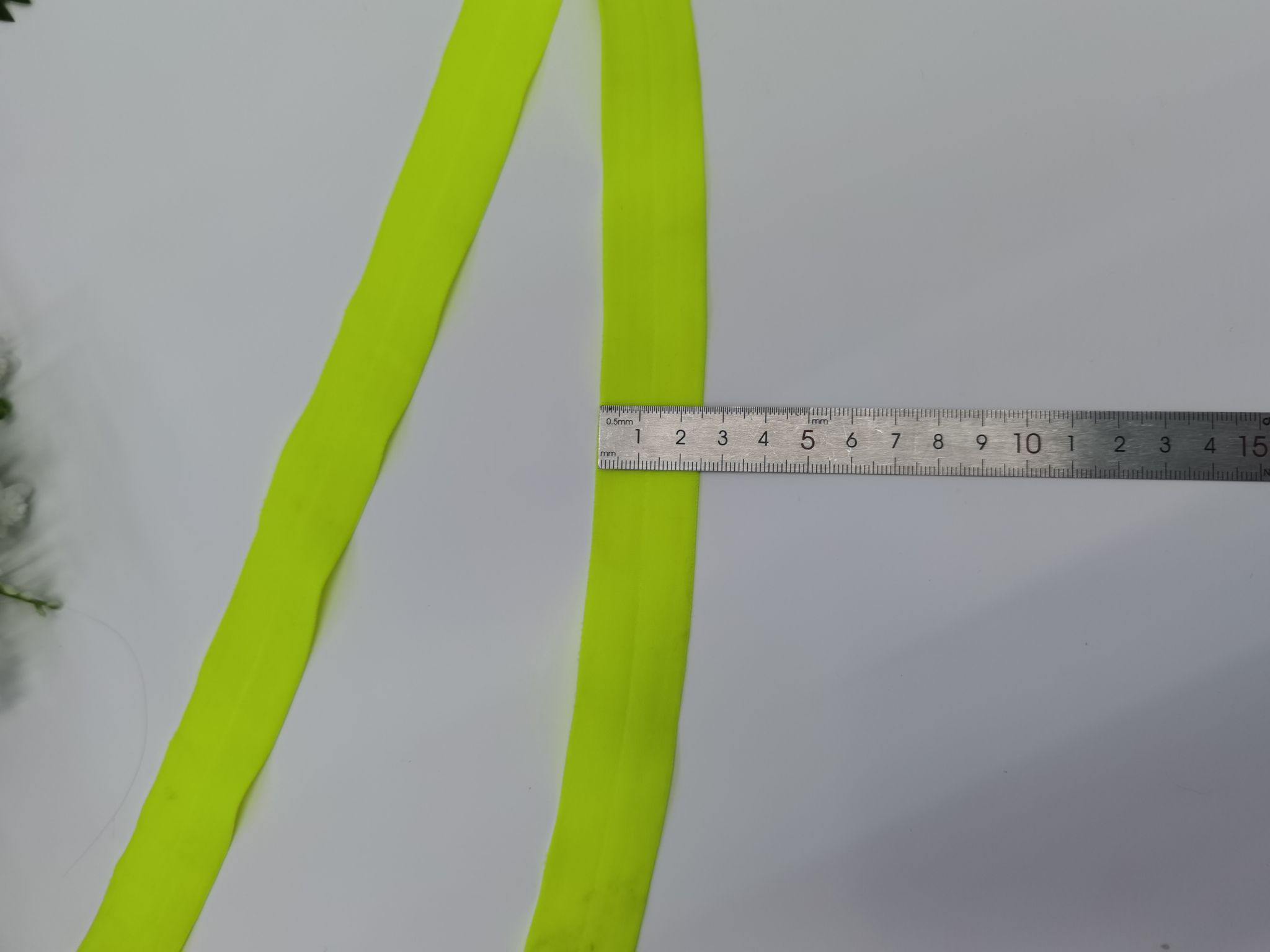

In today's competitive manufacturing environment, the control of every detail can be the key to success or failure. This factory-sold, tailor-made adjustable edge tool provides unprecedented flexibility and reliability for various difficult application scenarios with a precise adjustment range of 0.4 to 4.0. Whether it is a lightweight assembly workshop or a heavy-duty processing plant, it can rely on it to complete a nearly perfect cutting task.

Flexible control of subtle differences | Why the 0.4-4.0 adjustment range has become the industry benchmark

From the corner treatment of ultra-thin metal parts to the trimming of heavy equipment parts, the requirements for dimensional errors are becoming more and more stringent. This wide coverage and small step adjustment system can not only adapt to regular tasks, but also cope with the extreme challenges under special working conditions, and achieve the ideal processing effect under the premise of ensuring the strength. The change of each small unit means a higher level of quality leap, helping users overcome the bottleneck of traditional processes.

Craftsmanship Builds Core Competitiveness | Every Design Serves Efficient Productivity

the professional structure developed by combining ergonomic principles and mechanical balance model makes the operation more labor-saving and smooth; the high-strength alloy material endows it with lasting wear-resistant vitality; and the anti-slip texture on the surface greatly enhances the sense of grip security, allowing you to focus on every precision cutting link. A security mechanism that has been tested and verified millions of times protects every user's work rights from being compromised.

A Model of Cross-border Applicability | How It Won the Deep Trust of Multiple Industry Customers

whether it is the repair of body sheet metal in auto repair plants, the chamfering and polishing of electronic product shells or the pretreatment of large quantities of parts on automated production lines, this multi-functional sharp tool has shown convincing performance-the high adaptability under unified standards is the reason why many enterprises choose it. Successful cross-domain deployment proves that its practical value is much higher than that of similar competitors.

The Secret Weapon to Achieve Customer Value Leap | Actual Cases Reveal Its Actual Effectiveness

feedback from many cooperative factories shows that after the introduction of this edge adjustment equipment, the defective rate of products has decreased significantly, the delivery cycle has been greatly shortened, and the loss of manpower and material resources caused by repeated debugging has been saved. This is not only a tool, but also a power engine to promote industrial upgrading. Many first-line engineers said that since the adoption of this series of products, the entire production line has taken on a new look.