What is the 0.4-4.0 edge? Explaining the industry implications behind the specifications

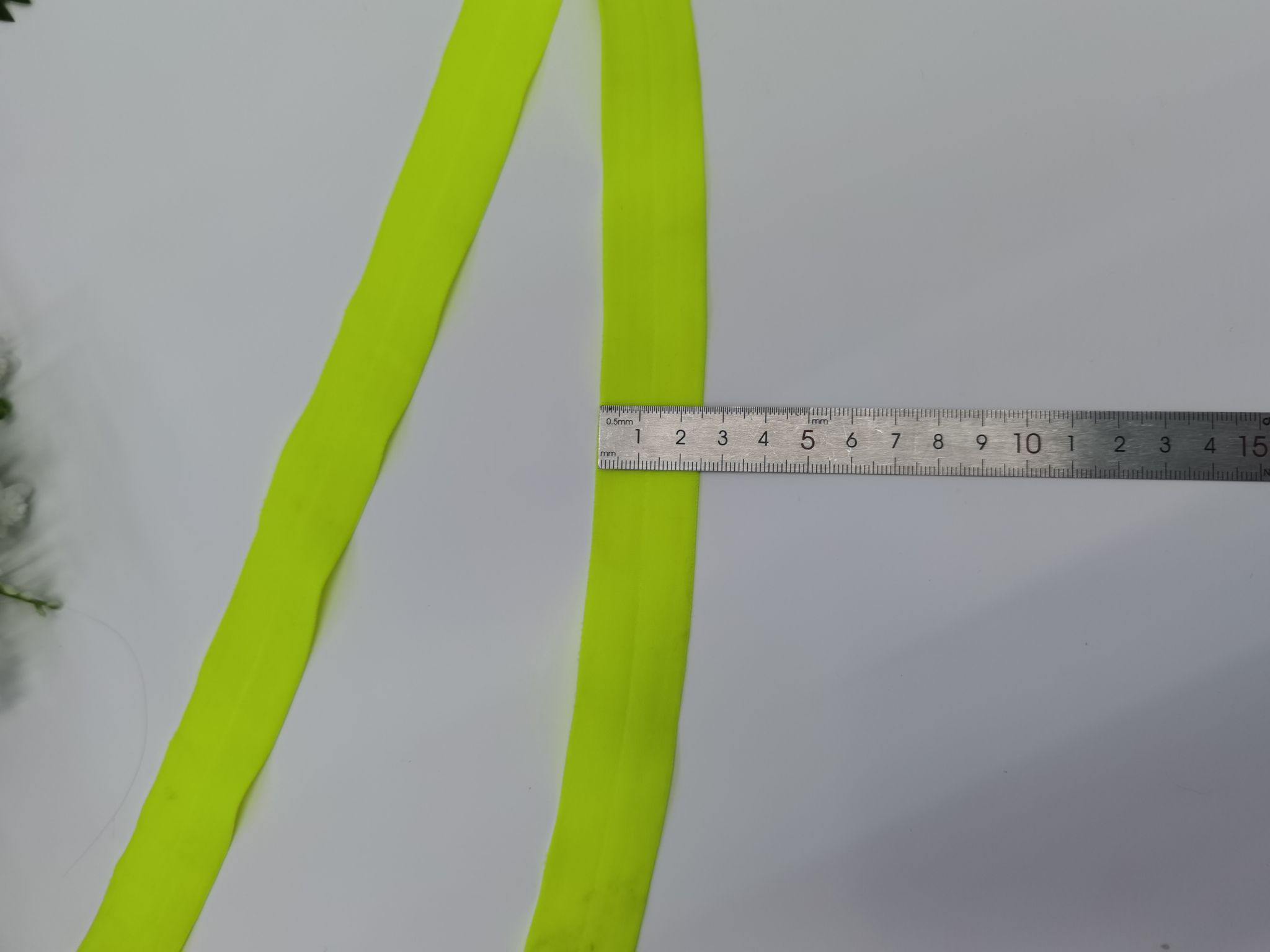

In the modern industrial system, the dimensional accuracy of the product directly affects the operating efficiency and product quality of the entire production line. The term "0.4-4.0 edge" refers to high-performance cutting or forming tools suitable for this specific width range, which play a vital role in precision manufacturing processes.

this value is not set out of thin air, but the best matching interval is obtained after considering the general interface specification of mechanical equipment, the difficulty of material processing and the cooperative operation of the whole system. Because of this, it is widely used in various automated assembly lines and high-end equipment manufacturing scenarios, and has become the "golden ratio" in the minds of engineers ".

The advantages of the factory direct sales model are highlighted: the value embodiment of eliminating intermediate links

Compared with the phenomenon of price increase caused by traditional multi-layer distribution channels, the sales strategy of "factory through train" is obviously more competitive. On the one hand, the absence of a third-party intermediary means that the quotation is more open and transparent, which greatly reduces the budget pressure of the enterprise in the procurement of raw materials; on the other hand, the after-sales technical support can directly connect with the original factory team, thus greatly improving the response speed and service quality.

Many business leaders report that since they changed to directly contact the manufacturer, they have not only obtained a lower cost expenditure plan than before, but also can enjoy a one-to-one personal tracking service experience. This change is gradually Transformed into stronger business operation efficiency.

Technical Highlights Full Analysis: What Makes It Top of the Top Selling List?

The reason why we can stand out in the fierce market competition and maintain a leading position for a long time is inseparable from a series of solid and reliable technical endorsements. First of all, the basic components with extremely high wear resistance are selected to maintain good functional status even in the face of extreme working conditions. The second is to use advanced numerical control machine tools to complete fine operation steps to ensure that every millimeter error is accurately calibrated before leaving the factory.

In addition, there are a number of patent-certified design innovations, such as rapid replacement mechanism, self-lubricating bearing structure, etc., which have further consolidated its position as a benchmark product in the industry and won high recognition from customers around the world.

Broad application scenarios at a glance: What key industry areas are covered?

Thanks to the excellent functional diversity, this core equipment has already played a role in many key industrial chains. For example, in the automotive industry, one of the key components of the fixture adjustment mechanism for parts on the conveyor belt is such products; while in the home appliance manufacturing workshop, it often acts as a bridge between the circuit board and other robotic arms.

In addition, there are many application cases in high-demand environments, such as special fastening elements required in the aerospace equipment assembly area and precision bracket construction units for medical devices, which fully prove its actual combat capability and wide application potential.

Customer Real Feedback: Why Are They Willing to Repurchases and recommend?

First-line users from all over the country have generally given positive comments. Many people mentioned that they were attracted by the intuitive operation interface when they first came into contact, and the subsequent actual use stage was even more pleasantly surprised-the start-up time of the equipment was significantly shortened, and the daily output was steadily increasing while the non-performing rate was also The rate has dropped a lot.

More importantly, unplanned downtime maintenance is rare, significantly reducing the cost of human maintenance and the associated risk of financial loss. Many old customers have taken the initiative to introduce peer friends to discuss cooperation matters, forming a good word-of-mouth communication effect.

Future Trends: Where will this product go?

As the pace of global intelligent manufacturing transformation accelerates, it is expected that a new wave of upgrades will be ushered in for existing models in the next few years. Including the introduction of the Internet of things intelligent monitoring module to achieve remote diagnosis and early warning function, to help users find hidden problems in advance to avoid major accident losses.

another direction worthy of attention is the research and development efforts around the theme of energy conservation and emission reduction, including but not limited to the use of recycled materials to reduce cost consumption levels, improve production processes to reduce carbon emissions and other measures have been implemented one after another, laying a solid foundation for the already outstanding products to continue to maintain a strong momentum of development in the future.