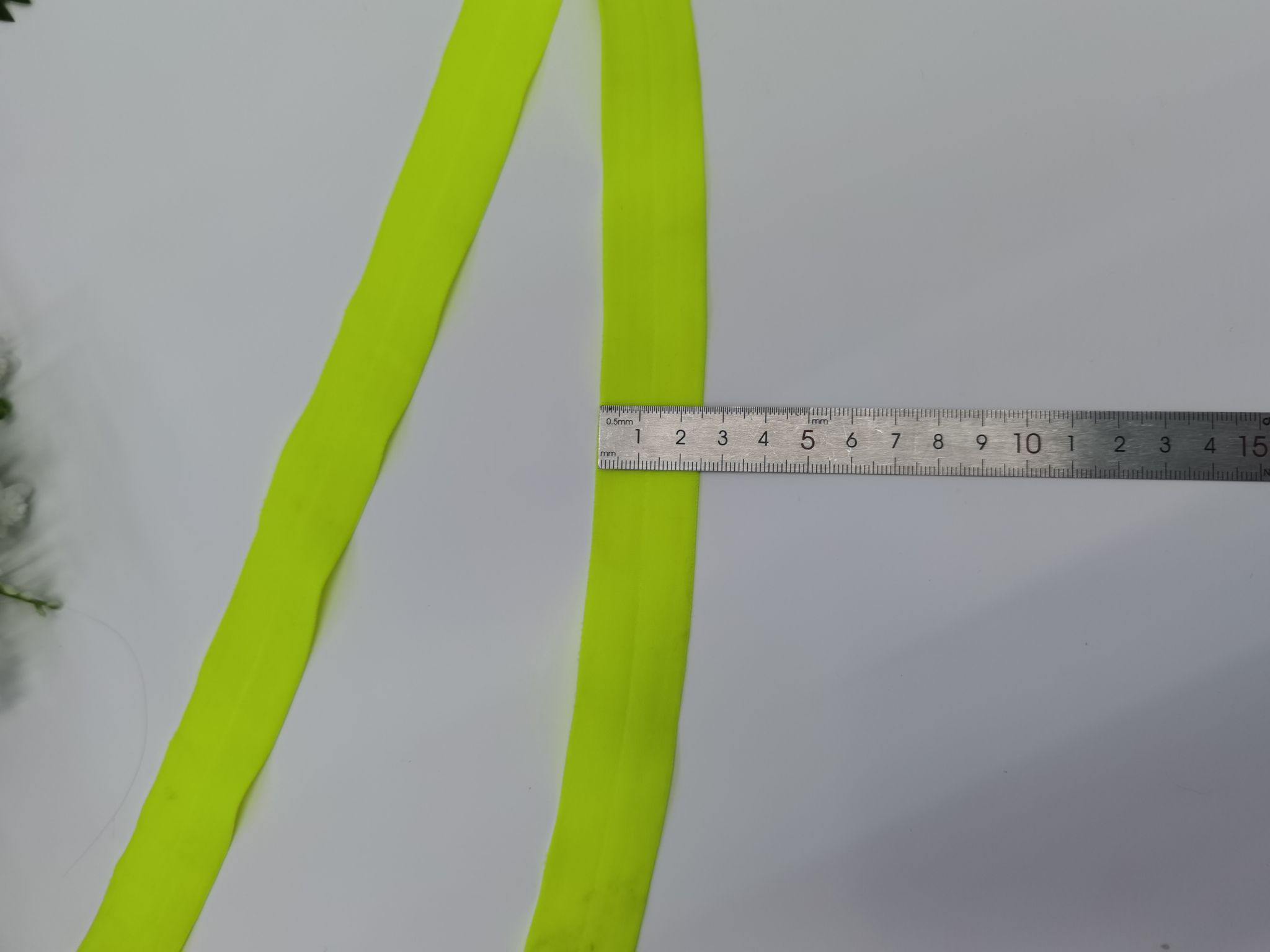

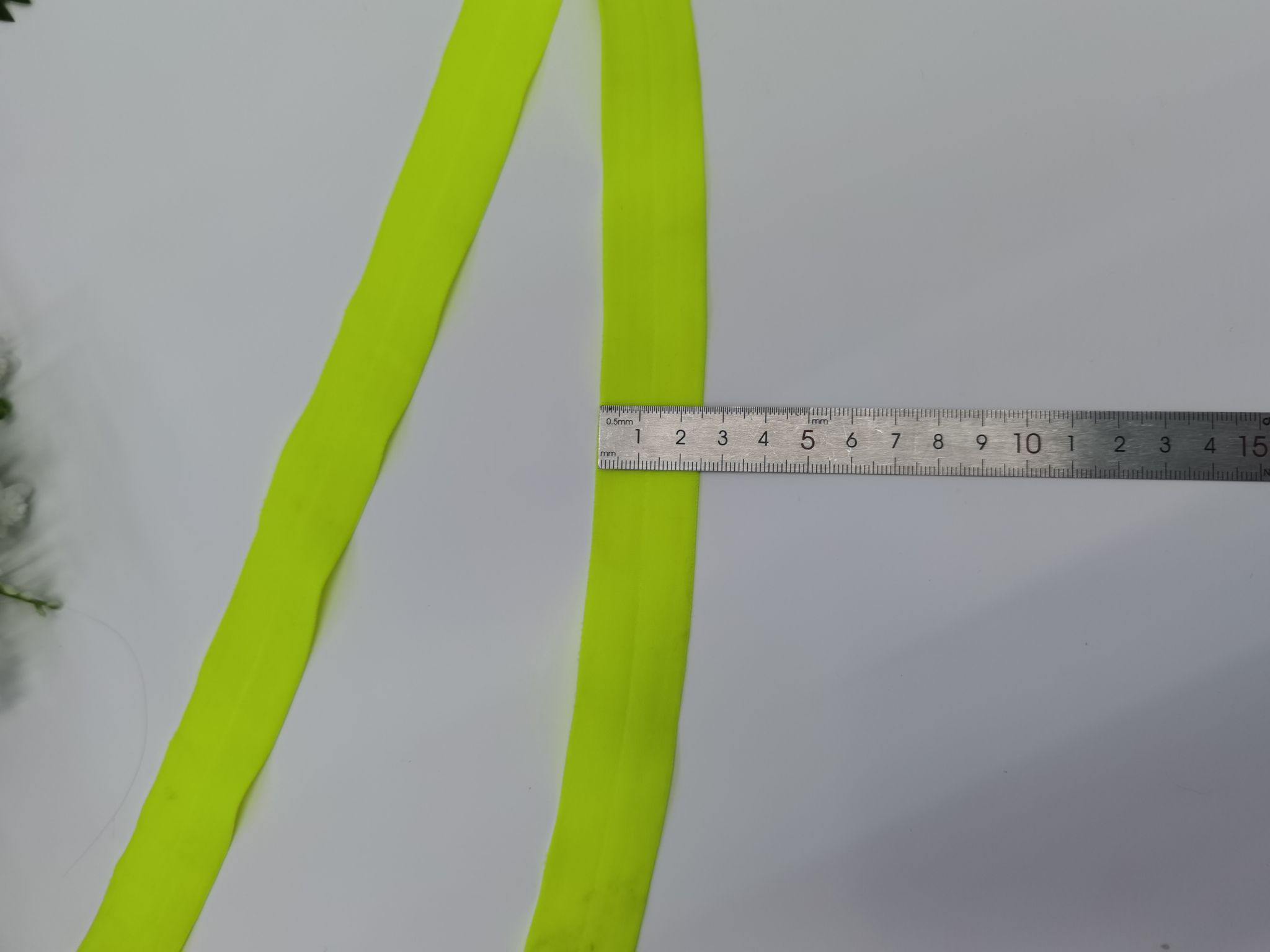

In the context of accelerating the evolution of the global manufacturing industry to intelligent, "factory direct sales from the best 0.4-4.0 edge" stands out for its excellent cutting performance and wide range of applications. It not only redefines the standard of modern cutting tools, but also becomes an indispensable key force for many enterprises to improve quality and efficiency.

Precise process definition industry benchmark

This innovative product combines the latest nano-surface treatment technology and multi-axis CNC fine grinding process to achieve an unprecedented balance of sharpness and long-lasting durability on the micro-scale.

Each factory blade undergoes an extremely rigorous quality inspection process to ensure that its geometric dimensional errors are controlled within the micron level, thereby providing users with consistent and reliable cutting results.

Wide Adaptability Achieve All-round Tool

Whether it's fine carving on thin and light plates or the challenge of strong stripping of heavy materials, this system has shown impressive adaptability.

It can seamlessly dock a variety of automation equipment, including fiber lasers, and support various specifications of clamping devices to match the installation requirements, and truly achieve a multi-purpose machine to meet complex and diverse application requirements.

Performance Upgrade Drives Intelligent Manufacturing Transformation

The secret of maintaining stable output performance in a long-term high-intensity working environment lies in the unique aerodynamic cooling channel layout and the combination of functional units that are easy to disassemble and replace.

This makes maintenance extremely simple and fast, and greatly reduces the economic losses caused by the shutdown due to unexpected failures.

Practical Cases Witness Word of Mouth Leap

Many large auto parts suppliers have reported that the number of defective products has dropped significantly since the adoption of this series of tools, and even reached the ideal level below the national emission standards.

In addition, many home appliance manufacturers have made breakthroughs in doubling their output through targeted improvements to their original production lines, fully demonstrating their strong practical value.

Green Intelligent Manufacturing Practice Sustainable Development Strategy

the concept of actively responding to the call of carbon neutrality runs through the whole research and development production chain-giving priority to raw material source channels with high utilization rate of renewable resources from the stage of material selection at the source.

According to statistics, compared with regular options on the market, their average power consumption per unit has been reduced by about 1/5. The fluctuation range within the ratio range is small, which is easy to arrange for budget control and implementation plan.

Meticulous Attitude Makes Extraordinary Quality Foundation

If you are looking for an ideal alternative that can greatly increase productivity and meet the demands of energy conservation and environmental protection, then you may as well experience it yourself! At present, when placing an order during the promotion season, you will also enjoy exclusive discount benefits waiting for you to come to unlock and obtain oh ~