In the field of industrial manufacturing, precise edge specifications often determine the performance and service life of the final product. This article will take you deeper into the application advantages of high-quality materials ranging from 0.4 to 4.0mm, and reveal why these products are the first choice on the purchase list of many enterprises.

Legend: Schematics of various types of precision machined parts we provide.

As a company committed to providing high-quality services, we know that the core issue of customer concern is the balance between price rationality and product quality stability. By adopting the factory direct supply model , not only can we significantly reduce the additional costs of intermediate links, but also ensure that each batch of goods can be produced and inspected according to strict international standards.

Not only that, this direct connection also brings customers a more convenient and efficient communication channel. Whether it is in the initial consultation stage of the project or any questions encountered in the later maintenance process, you can get timely and effective answers and support from the professional team.

Diverse applicable scenarios

With excellent technical strength and service level, our products have been widely used in many industries such as construction, auto parts assembly and electronic equipment manufacturing:

- Construction engineering: High-strength steel plates are used to support structural frames to build a safe and reliable living environment;

- Transportation: Lightweight aluminum alloy sheet significantly reduces vehicle weight and improves fuel economy index;

- Consumer Electronics: Precision stainless steel stamped components ensure durable and beautiful smartphone and tablet cases.

Example: A well-known mobile phone brand chooses the metal back cover parts produced by our company to share the case.

Customer Success Story

Company A is a high-tech enterprise focusing on the research and development of new energy battery pack systems. Before establishing a long-term cooperative relationship with us, it faced a serious problem of raw material inventory backlog. After many field visits and technical exchange meetings, we decided to try out a batch of lithium-ion electrode foil materials with a thickness of about 2mm supplied by us. Facts have proved that this choice is very correct-thanks to the stable and consistent control of geometric parameters and the highly competitive price system, Company A will continuously set new sales records in the next few quarters and smoothly expand its overseas market layout plan.

Transparent management leads to higher trust

in order to further strengthen the relationship with our partners, we also take the initiative to open part of the production line visit appointment rights to interested friends to come to understand how the entire production process works:

- The initial feeding preparation process includes cutting, cleaning and other preliminary processing steps;

- then enter the core hot rolling and cold drawing forging unit to complete the basic form shaping work;

- finally, it is necessary to go through multiple quality inspection checkpoints to confirm that all finished products meet the expected requirements before packaging and delivery.

One of the interior exploration series: a modern intelligent workshop with unobstructed views.

How to choose the best product for you?

although there are a large number of product models from competitors claiming to have similar functional characteristics to choose from, the following key factors still need to be considered before making a final decision:

first, what is the load condition limit value under specific application scenarios? Secondly, is there any special preference setting value for surface roughness? Finally, to judge the cost-effective ranking within the budget and then make a trade-off comparison to conclude.

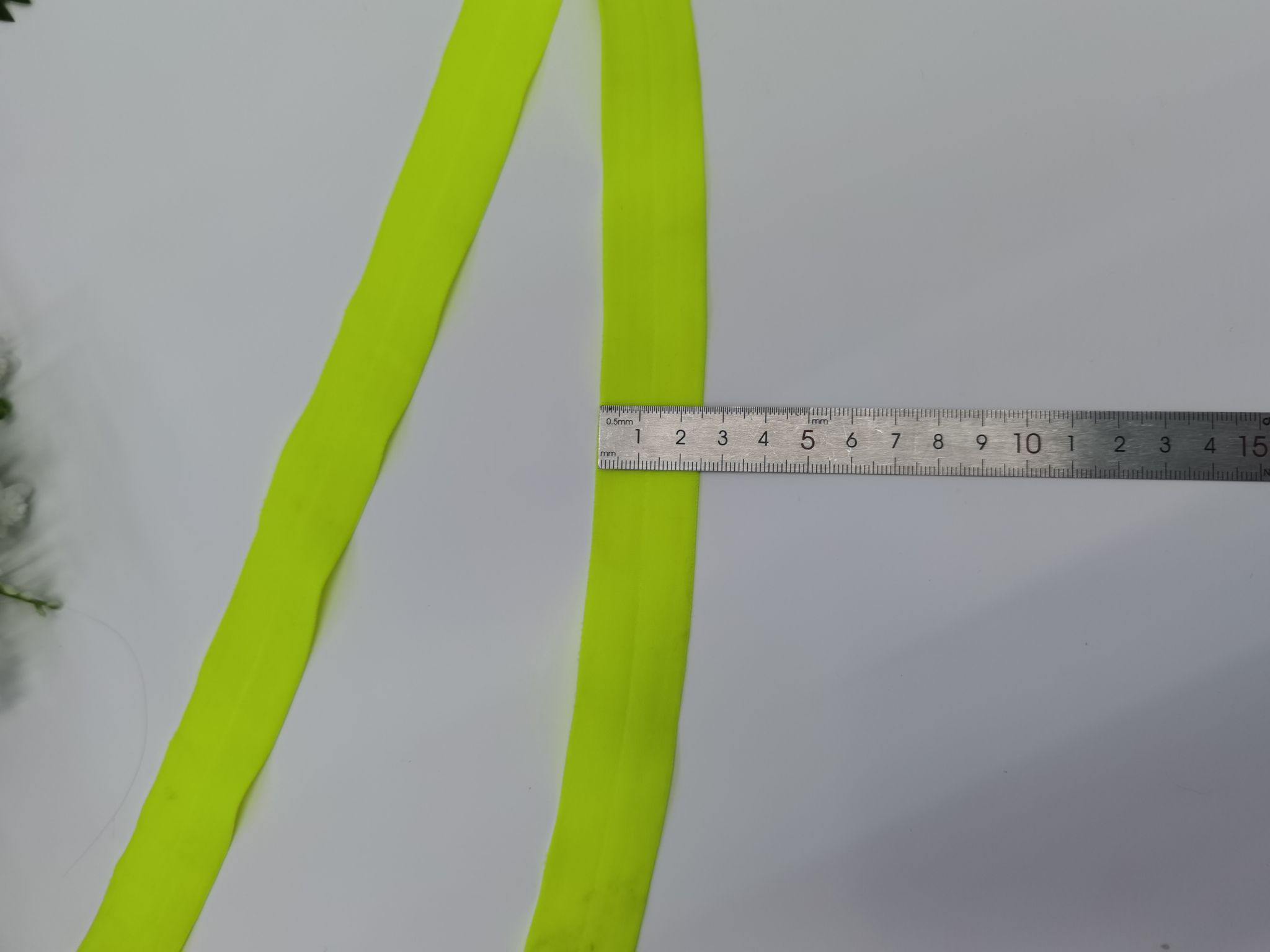

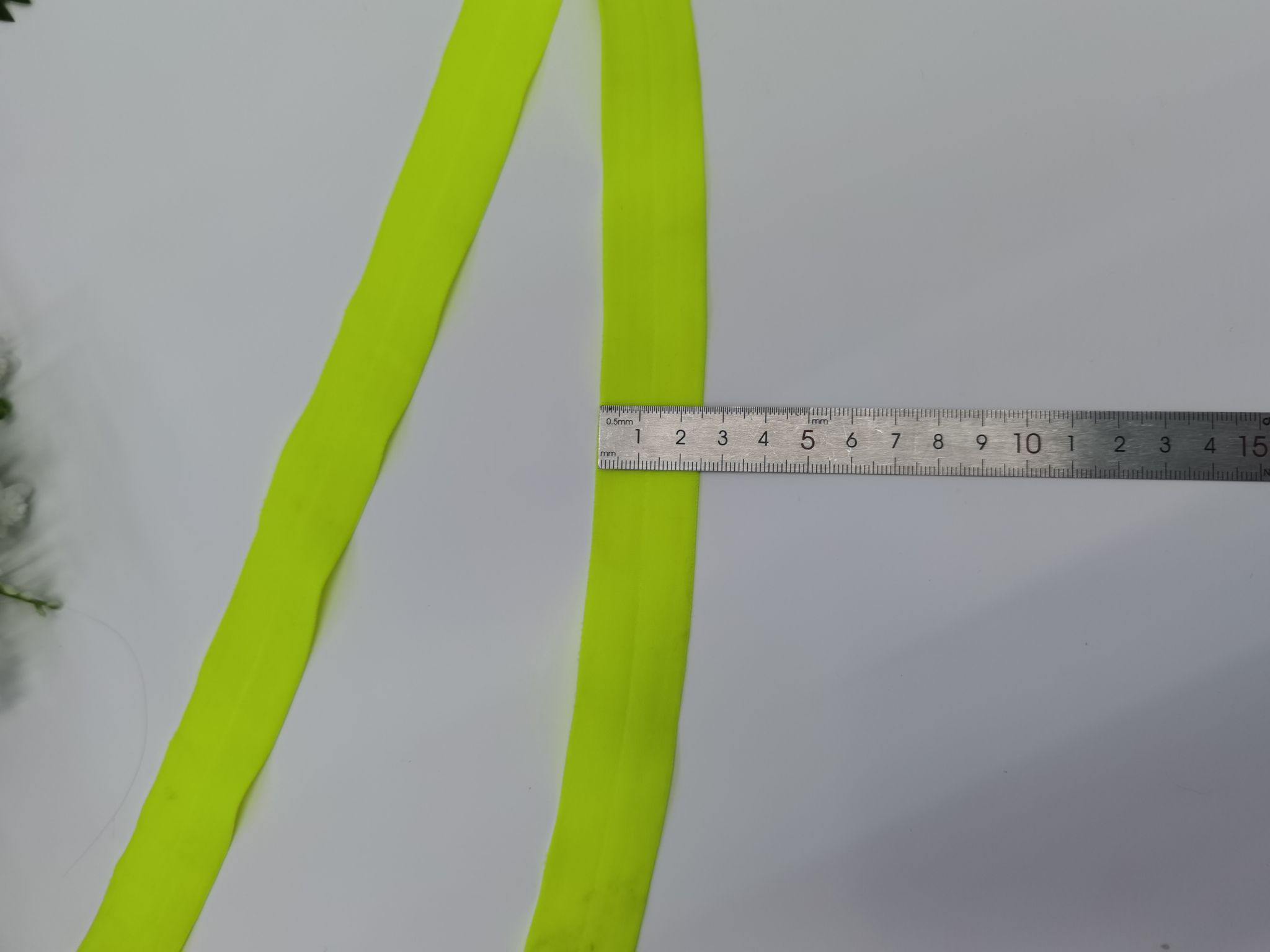

Auxiliary tools: Visually present the difference points of various physical and chemical properties to facilitate rapid screening of target objects.

in a word, only by thinking from the perspective of users can we create good things that conform to the trend of the times and can effectively solve the actual pain points. I hope the above content can inspire readers and friends. At the same time, please feel free to contact customer service for more information!